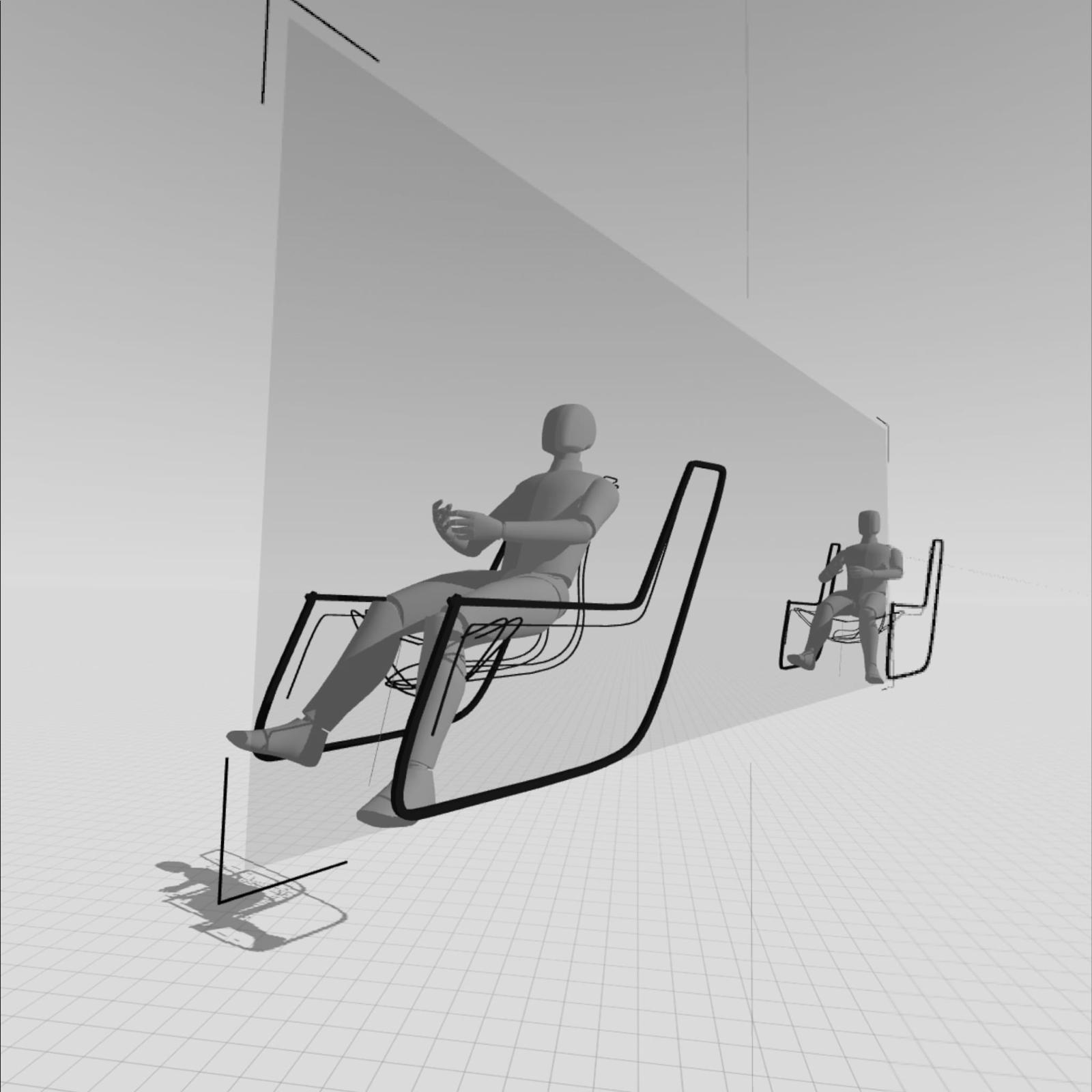

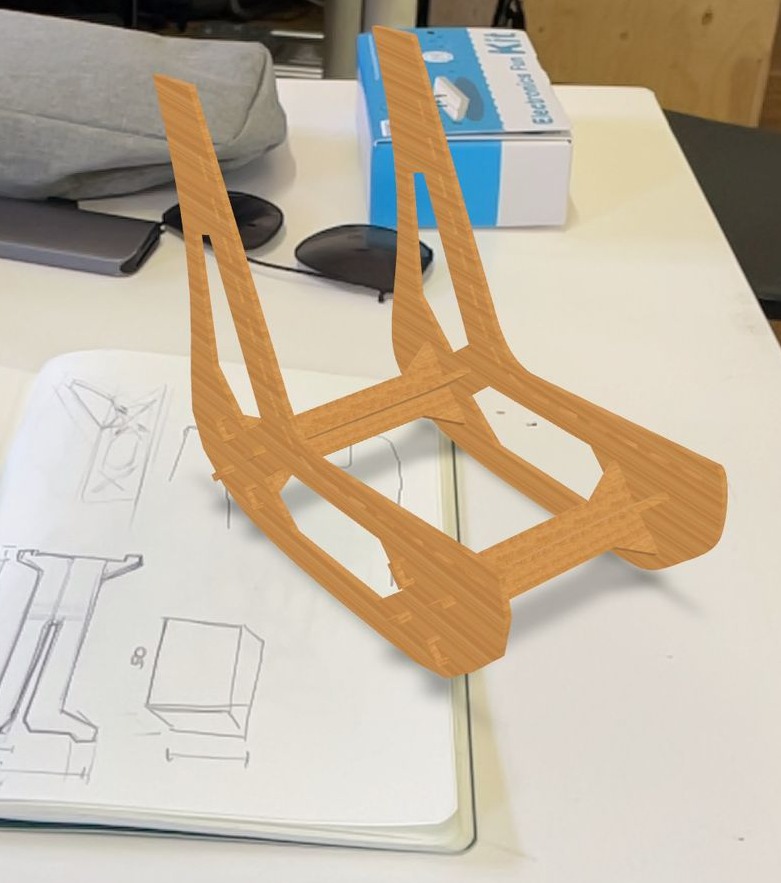

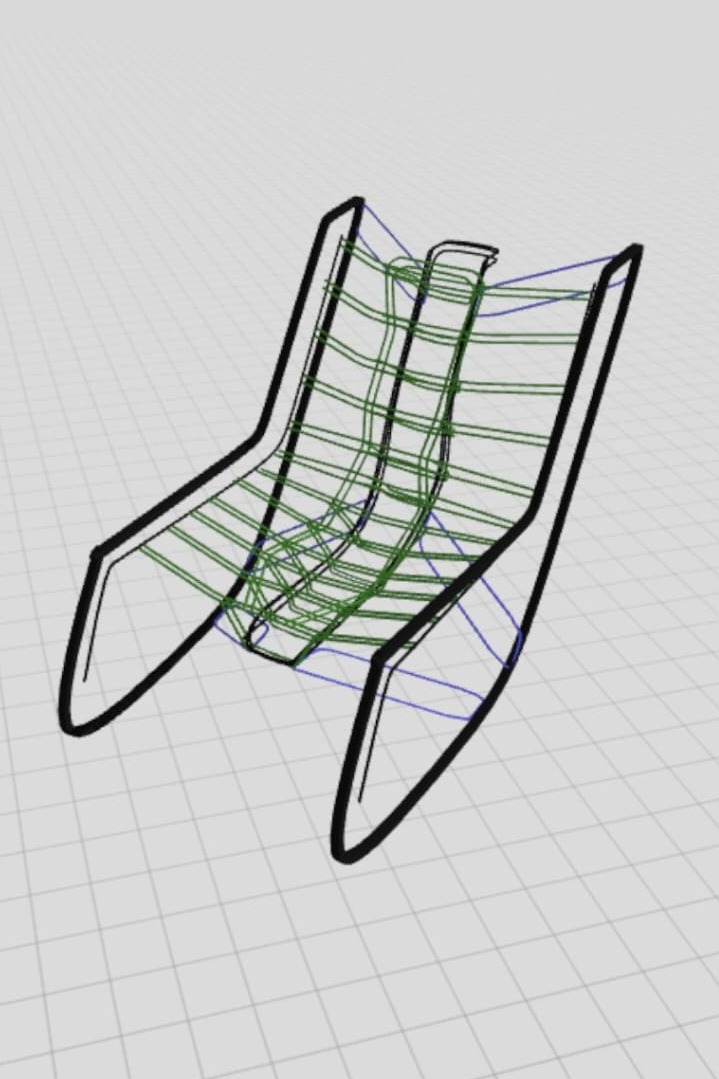

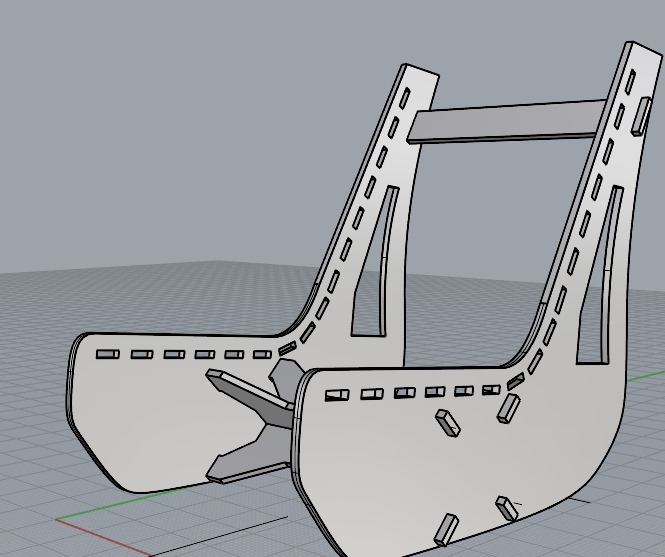

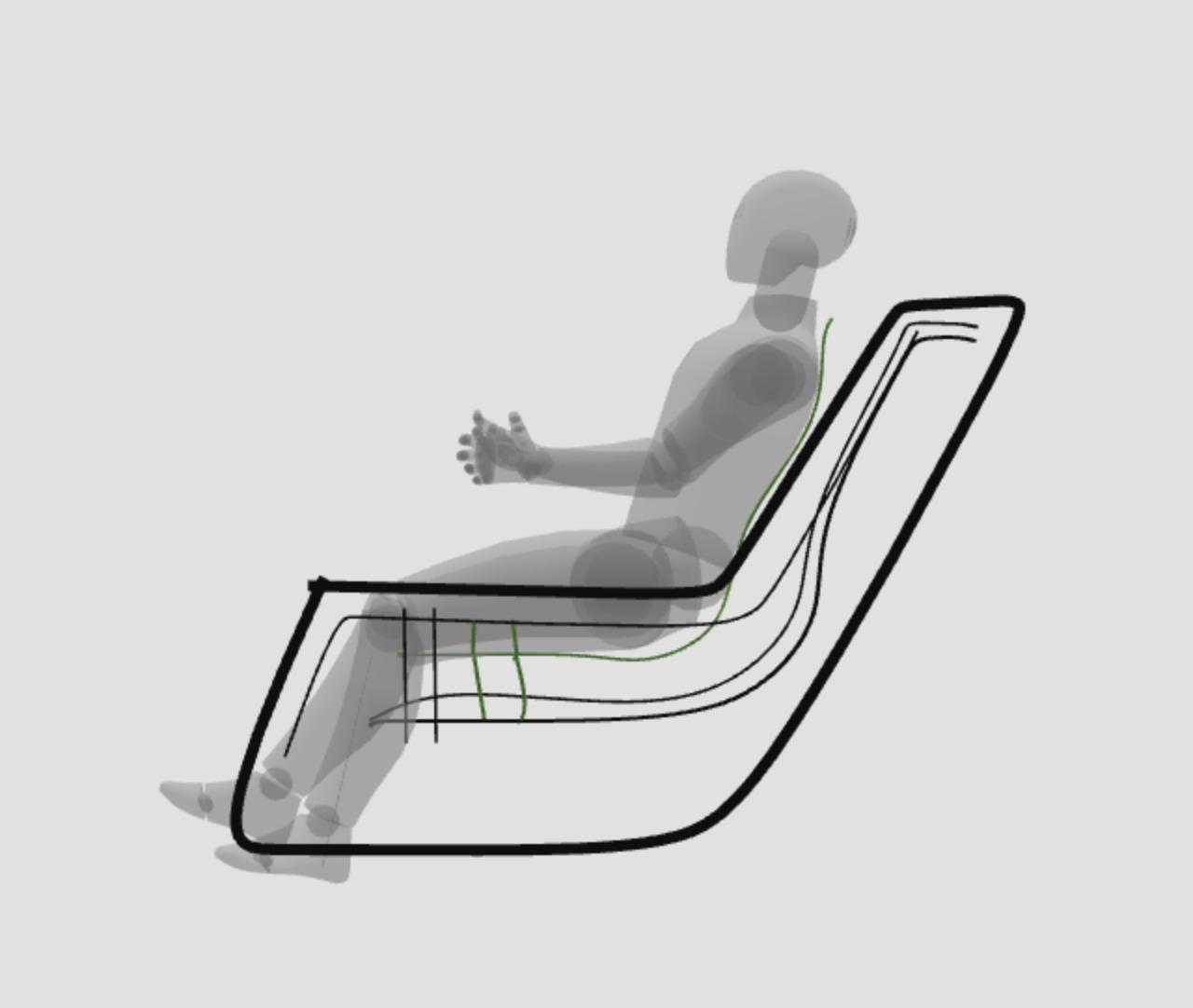

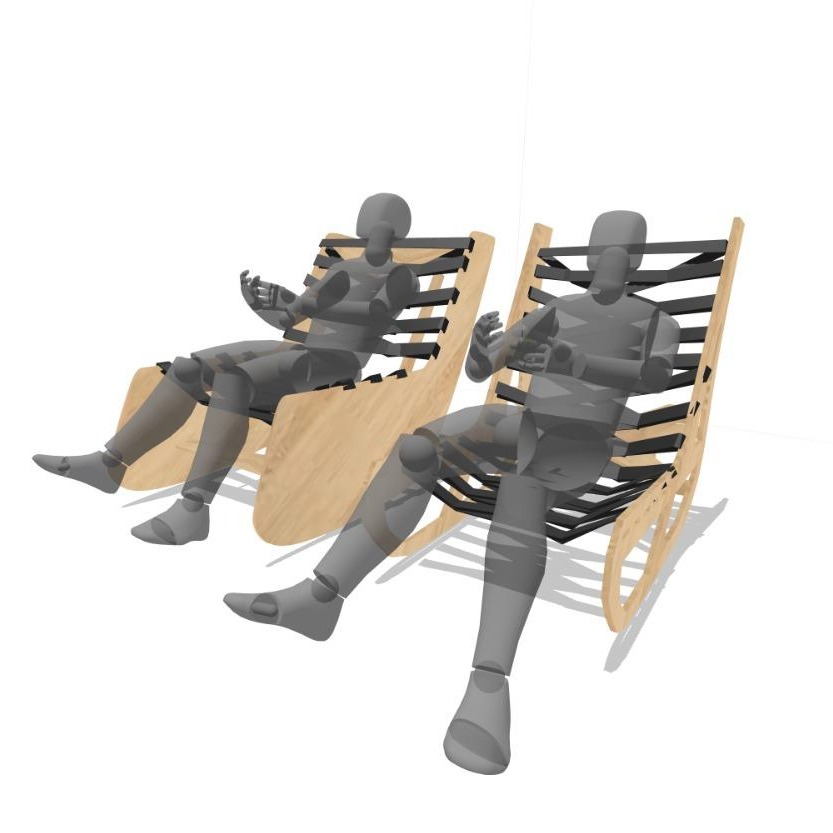

First Sketches

Once we decided we wanted to design a chair we started looking online for some inspiration of rocking chairs and low chairs. We then went through an iterative process of sketching on paper and in gravity sketch. We ended up needing to consider various element: Amount of wood we have, CNC requirements, time constraints and spacing for supports. Due to this the design has altered slightly from the original idea sketch.